Onsite Thread Repair

Client: Confidential

Industry: Power Generation

Location: UK

Duration: Completed within Hours

Service: Onsite Thread Repair

Overview

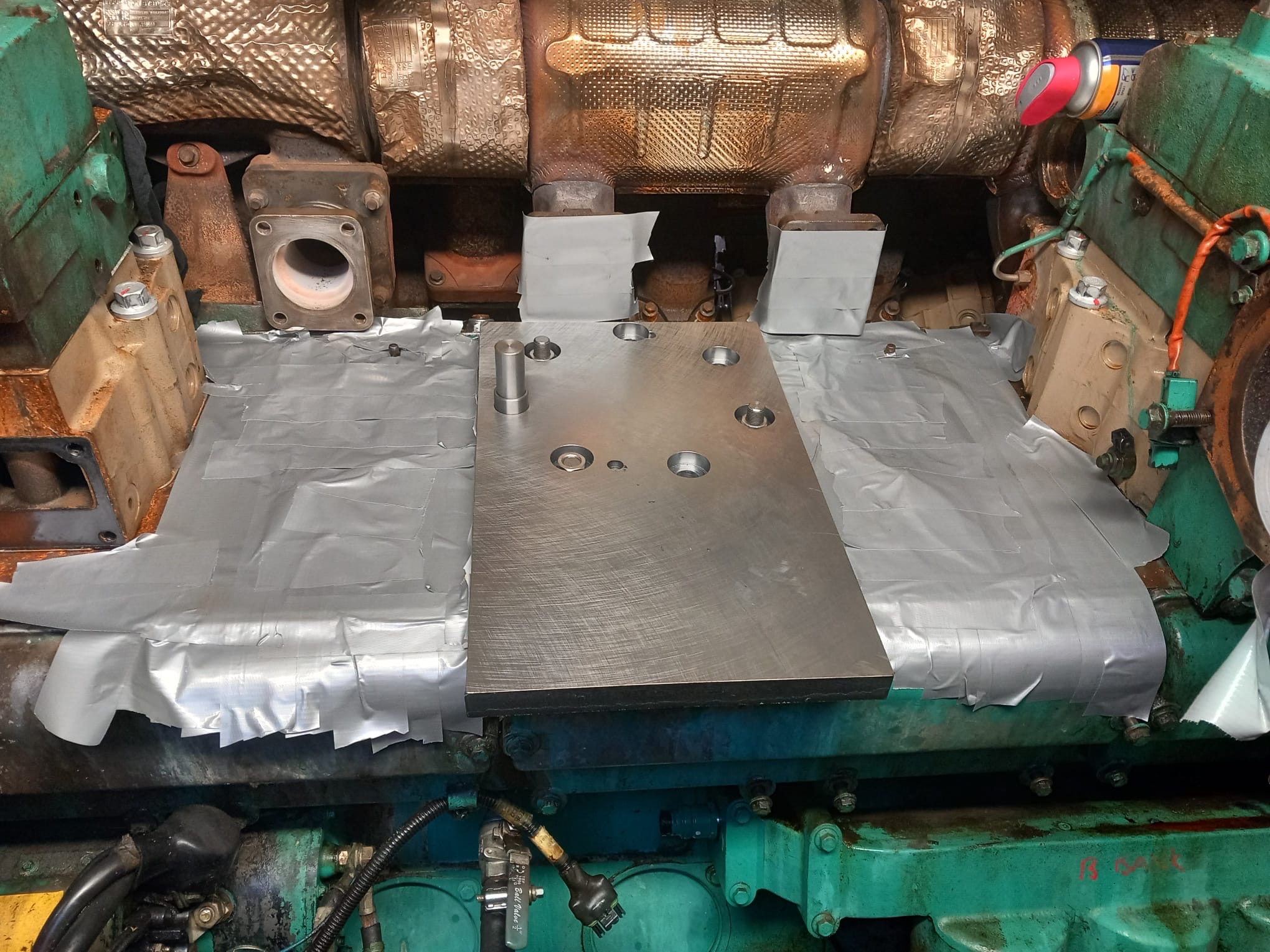

Royce Onsite Machining was engaged to carry out an urgent in-situ thread repair on a critical power generation unit. The threaded connection had failed, risking extended downtime and potential component replacement. To avoid disassembly and operational delays, the client required a rapid on-site recovery. Royce supplied and fitted a precision-engineered oversize insert, fully restoring the thread to OEM specification — all without removing the component from its assembly.

Work Carried Out

Damage Assessment

- Inspection revealed stripped or damaged threads.

- Non-destructive testing confirmed that the surrounding material was suitable for repair.

Oversize Thread with Insert

- Royce supplied a custom oversize insert, designed to restore thread integrity and strength.

- Using in-situ precision machining, the damaged threads were prepared to accommodate the insert.

- The insert was fitted and secured, restoring the connection to full operational specification.

Finishing and Verification

- Non-destructive testing confirmed mechanical integrity and alignment.

Technical Highlights

- Repair Method: Oversize insert, supplied and fitted by Royce Onsite

- Thread Type: Restored to OEM specification

- Downtime Avoided: Completed in hours

- Surface Finish: Smooth engagement, consistent torque

- Verification: Non-destructive testing confirmed full restoration

Outcome

The repair was completed entirely in-situ within hours, avoiding component removal or replacement. The threaded connection was restored to full operational strength and reliability, minimising downtime and protecting critical assets.

This project represents another successful in-situ repair by Royce Onsite Machining, demonstrating the company’s ability to supply, fit, and restore oversize thread inserts quickly and to OEM standards under field conditions.