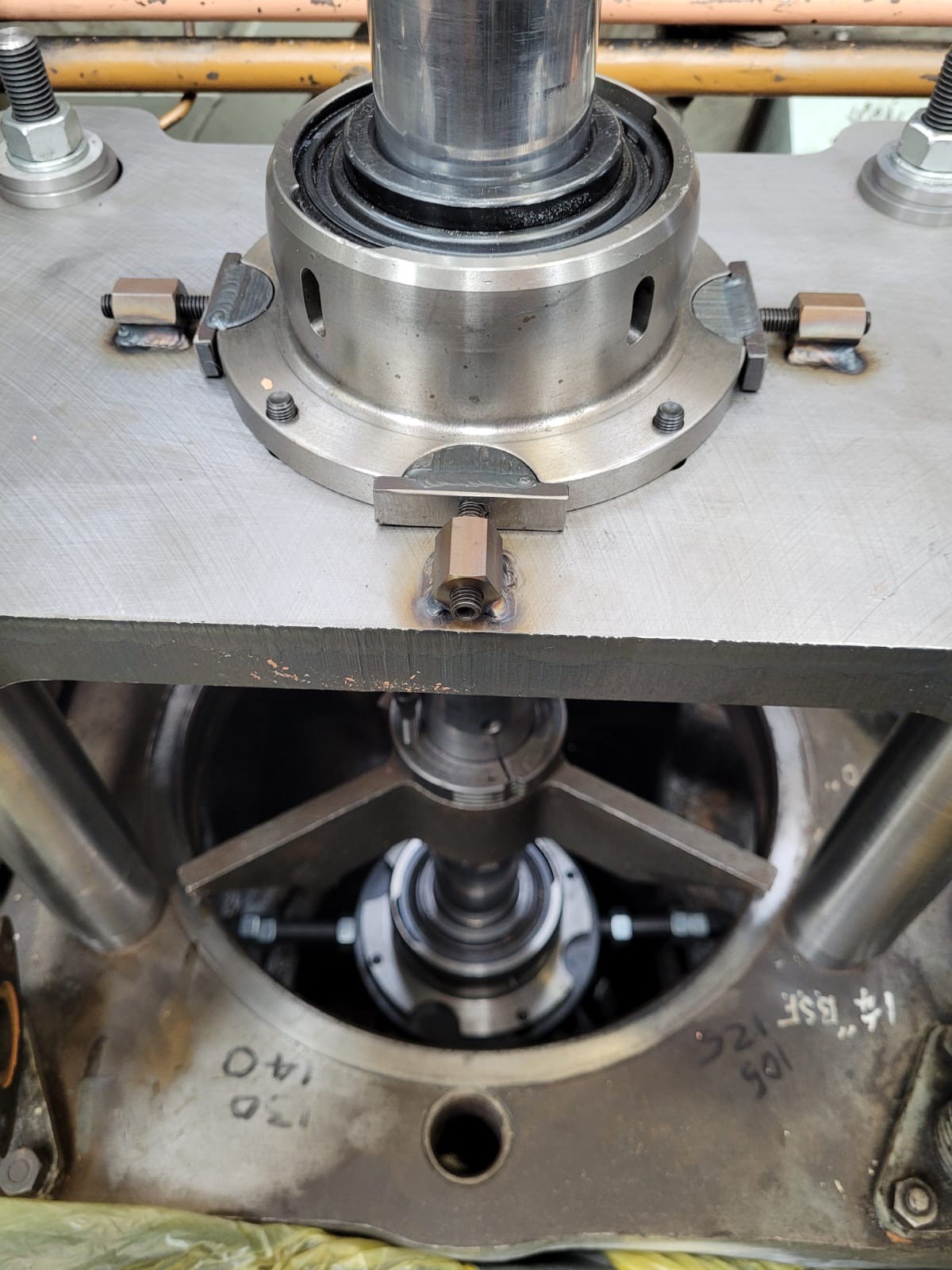

Precision Liner Landing Machining by Royce Onsite Machining

At Royce Onsite Machining, we specialise in liner landing machining and cylinder liner landing repair for engine blocks, cylinder heads, and sleeves. Whether preparing for new liner installation or correcting wear, corrosion, distortion or damage, we provide accurate in-situ machining of liner landing surfaces directly onsite to minimise downtime.

What Is Liner Landing Machining?

Liner landing machining restores the critical sealing surface at the base or top of a cylinder liner. This ensures:

- Correct liner height and protrusion

- Proper head gasket sealing

- Engine compression integrity

- Prevention of coolant and combustion leaks

When this area becomes worn, pitted, fretted or distorted, cylinder liner landing repair is essential to return the engine block to OEM specification.

Why Liner Landing Condition Matters

The liner landing forms the foundation of the combustion chamber. Any deviation from specification can lead to:

- Blow-by or combustion leakage

- Coolant ingress and overheating

- Premature head gasket failure

- Liner misalignment

- Loss of efficiency and increased fuel use

Accurate liner landing machining ensures the engine can be reassembled and operated with confidence.

When Is Cylinder Liner Landing Repair Needed?

Liner landing machining is typically required when you encounter:

- Incorrect liner protrusion or recess

- Corrosion or pitting around the landing surface

- Fretting or erosion from gasket movement

- Damage after a liner collapse or thermal event

- Block distortion due to overheating

- Wear after long service hours

Our technicians diagnose and correct these conditions onsite using precision measurement and machining equipment.

Our In-Situ Liner Landing Machining Services

We provide a complete range of onsite liner landing and cylinder block machining capabilities, including:

- Onsite liner landing machining for large engines (marine, rail, plant)

- Cylinder block counterbore and deck surface machining

- Liner seat restoration and clean-up

- Weld build-up and machining for damaged surfaces

- Measuring and correcting liner protrusion and recess

- Custom shim solutions for proper liner seating

Why Choose Royce for Liner Landing Machining

Liner landing machining is a precision-critical process. Any error in alignment, surface finish or depth can lead to expensive downtime. At Royce Onsite Machining, we have decades of experience carrying out high-tolerance in-situ machining on heavy industrial equipment.

All liner landing machining is carried out on site, removing the need to strip down and transport large engine blocks or components. This keeps downtime to an absolute minimum and avoids unnecessary handling risks.

We support marine, power generation, and heavy industrial sectors, where safety and reliability are non-negotiable.

FAQs – Liner Landing Machining & Cylinder Liner Landing Repair

What causes liner landing surfaces to wear or become damaged?

Corrosion, fretting, coolant leaks, overheating, and long service hours are common causes.

If the block or bearing housings are also affected, our line boring services may be required.

How long does onsite liner landing machining typically take?

Most liner landing machining work takes a few hours to one day per liner, depending on:

- The extent of wear or damage

- Accessibility

- Whether multiple liners require machining

- Whether weld build-up or counterbore work is required

For complex repairs involving structural cracks or block damage, metal stitching repairs may add time but prevent the need for block replacement.

Can liner landing machining be done onsite?

Yes. Our portable equipment restores the landing surface in situ without removing the engine.

What engines do you work on?

We machine liner landings on large diesel and gas engines across marine, power, rail and industrial sectors.

If crankpins or mains also need attention, we offer crankpin machining and crankshaft grinding machining.