Global Specialists in Crankshaft Machining

Royce Onsite Machining is recognised globally as a leading provider of emergency crankshaft machine repairs and crankshaft grinding machine services, supporting all major industries across every continent. With over 50 years of experience, Royce Onsite Machining has built an extensive knowledge base in crankshaft grinding machine repair and in-situ crankshaft machining.

Our expert teams quickly deploy a wide range of machining skills and techniques for crankshaft machine, crankpin, and main bearing repairs on both large and small engines.

We have successfully completed numerous complex on-site repairs worldwide, enabling our customers to avoid the costly and risky process of engine strip-down and remote workshop removal.

Get In Touch With Our Team Today

+44 (0) 1494 312 888

info@royceonsite.com

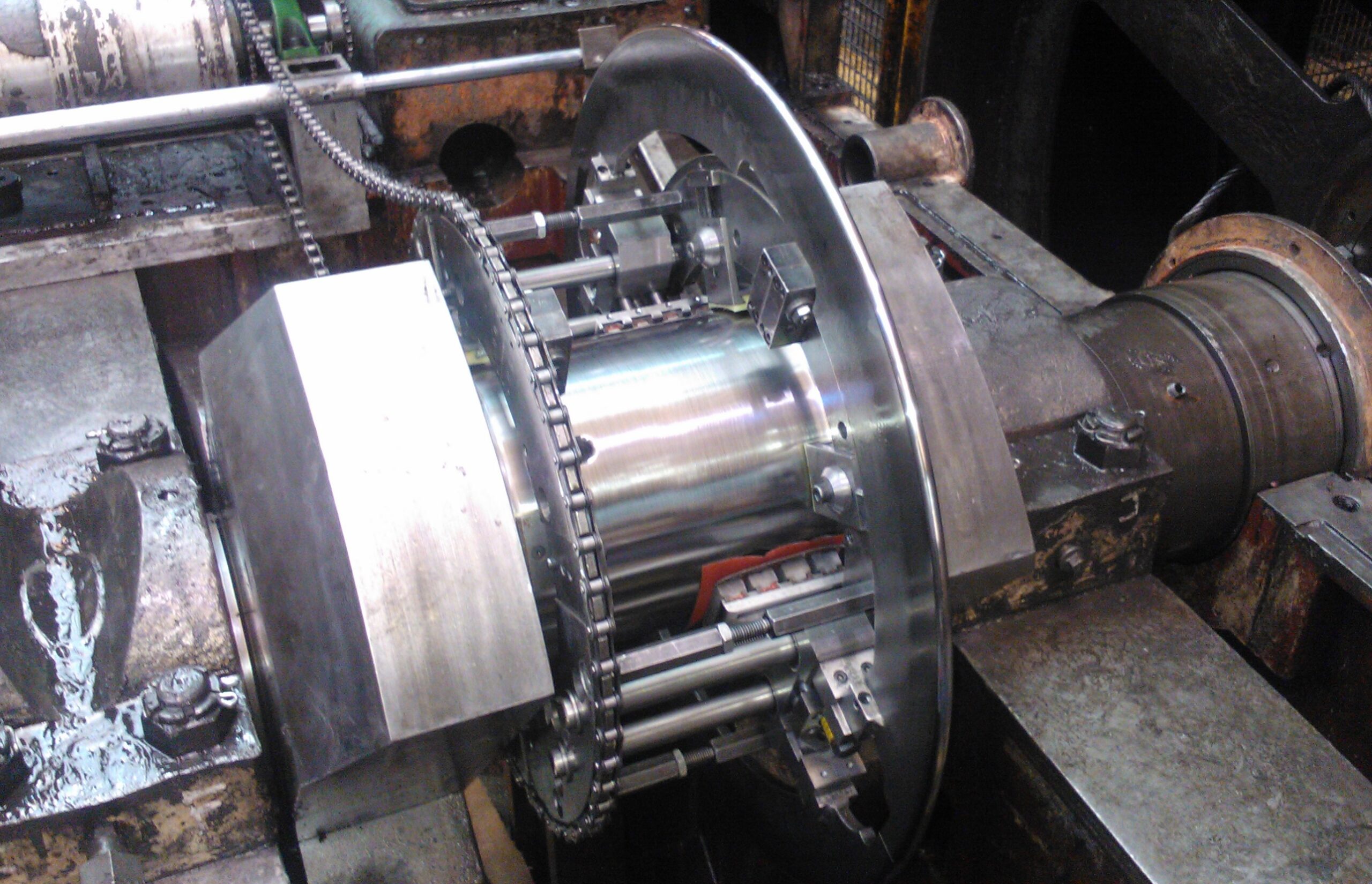

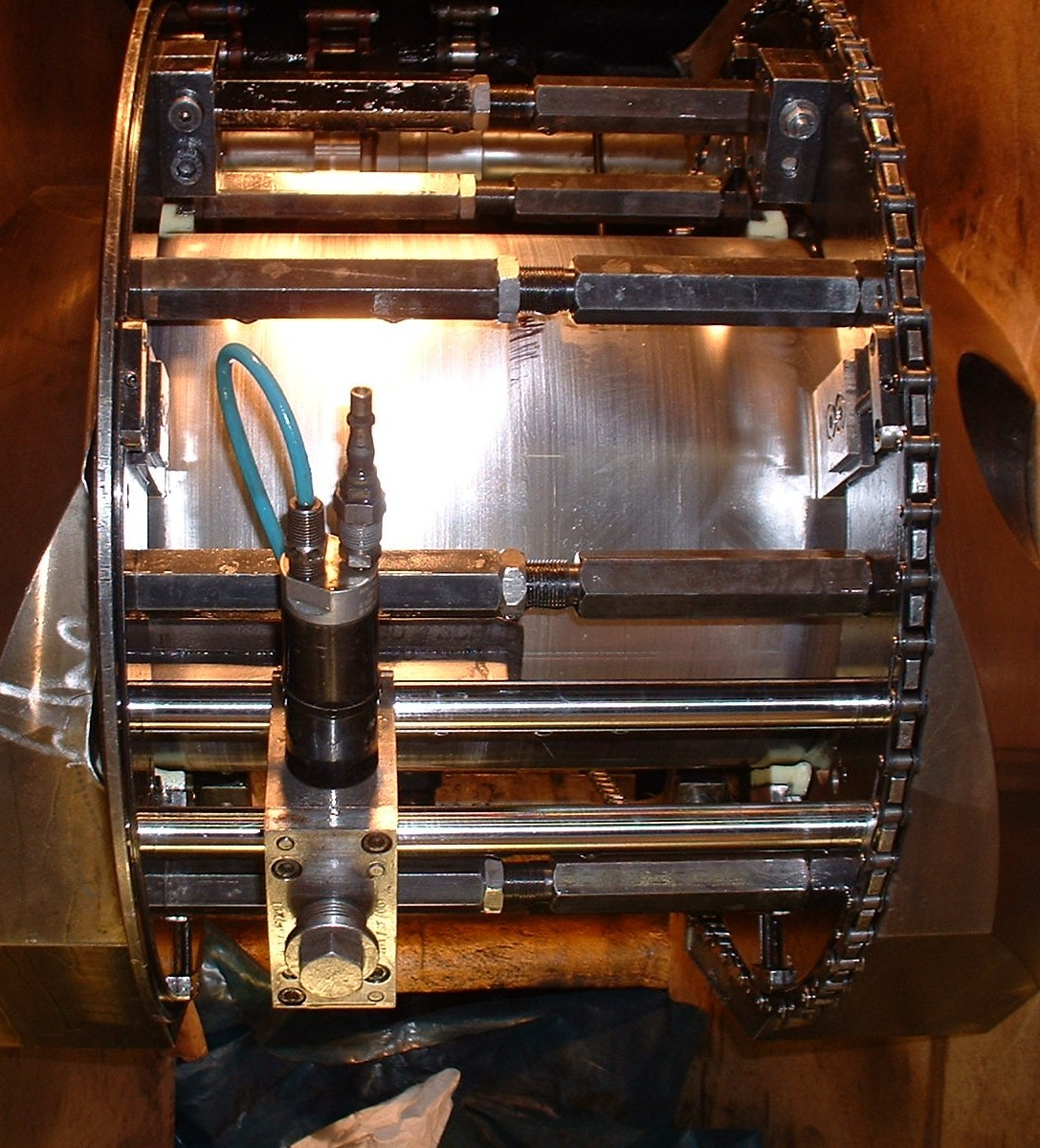

Advanced Orbital Machining Technology

Our crank grinder machine repair services utilise the latest orbital machining technology. Our skilled technicians specialise in refurbishing crankshafts, crankpins, and main journal bearings on land-based sites and aboard sea-going vessels. Our offshore-trained engineers are also available to travel worldwide, including offshore oil and gas platforms.

We maintain a vast inventory of portable orbital machining equipment, which can be shipped or hand-carried globally. Our equipment includes orbital turning, grinding, honing, and superfinishing tools that operate without shaft rotation. This allows us to machine and polish all sizes and shapes of crankpin journals (also known as “big end” or “large end” journals) and grind main journal bearings on-site, including for ship crankshaft machining repairs to precise OEM standards.

Industries and Equipment Serviced

We provide on-site crankshaft repair and grinding for a wide range of equipment, including:

- Diesel engine crankshafts (4-stroke and 2-stroke main and auxiliary engines)

- Reciprocating compressor crankshafts

- Forging press crankshafts

- Steam engine crankshafts

- Pump crankshafts

- Motor crankshafts

How Crankshaft Machining Services and In-Situ Crankshaft Repairs Work

In-situ crankshaft machining enables precision reconditioning of crankshafts without removing the engine from service. Using a portable crankshaft grinding machine, our engineers restore damaged crankpins and main journals to OEM tolerances.

Crankshaft Repair & Recovery Services

Royce Onsite Machining provides a full range of in-situ crankshaft repair and crank grinding capabilities, including:

- Rapid inspection of crankpin bearing journals and main bearing journals

- Non-destructive testing (Magnetic Particle Inspection) to detect cracks

- Electronic hardness testing

- Peen straightening for bent shafts

- On-site machining, grinding, honing, and superfinishing of crankpin and main bearing journals

- Annealing and portable heat treating to remove hard spots and heat damage

- Machining of counterbalance weight surfaces, including thread repairs

Why Choose Royce Onsite Machining

When critical machinery fails, time is everything. As soon as you get in touch with us, we’re ready to deploy anywhere in the world, whether that’s a ship in port, an offshore platform, or a remote power station. Our team handles the entire process without the need to remove or transport the component. This keeps downtime and costs to an absolute minimum.

Our management team brings over 50 years of combined experience, ensuring skilled technicians and the right equipment arrive exactly where and when needed.

Royce Onsite Machining has earned a reputation for delivering high-quality results on every on-site machining project worldwide.

Partnership with OEMs and Clients

We work closely with OEMs, engineers, and site managers to ensure every in-situ machining project is delivered efficiently and meets stringent industry standards. From initial consultation to project completion, our team prioritises clear communication, technical precision, and safety at every stage. Discover how we’ve helped business with their repairs today; Royce Onsite Machining Case Studies.

In-situ Crankshaft Machining FAQs

How long does it take to machine a crankpin?

With Royce Onsite Machining equipment, we can complete a crankpin within 24 hours of being onsite.

Our highly trained engineers use precision orbital machining systems designed for fast, accurate recovery of damaged crankpins. This allows us to minimise vessel or plant downtime and get your equipment back into service as quickly as possible. Turnaround time can vary slightly depending on access, crankpin size, and extent of damage, but we always aim to achieve completion within a single working day.

Do you offer heat treatment or annealing after grinding?

Yes. We provide heat treatment and crankpin annealing services to restore material strength after machining. This ensures the repaired crankshaft meets OEM hardness and performance standards.

How long does it take to grind a complete crankshaft?

All being well, we can complete a full crankshaft within 96 hours of being onsite.

The process involves careful inspection, alignment checks, and multi-stage grinding to restore journals to exact OEM tolerances. Our engineers work around the clock, using portable precision grinding and polishing equipment. Each crankshaft is finished with surface roughness and hardness levels that meet or exceed the manufacturer’s specifications, ensuring optimal performance and reliability.

Can a crankpin with heat damage be repaired onsite?

Absolutely. Royce Onsite Machining uses the latest technology to recover a crankpin after failure, while maintaining OEM standards throughout.

Heat damage often results in hardness changes, cracking, or surface deformation, but our advanced machining and metallurgical processes allow for full recovery without the need to remove the crankshaft from the engine block. We carry out hardness testing, dimensional inspection, and final polishing onsite to guarantee that the component meets the required mechanical properties before returning it to operation.

What other on-site services do you offer?

At Royce Onsite Machining, we are experts in a wide range of on-site machining repairs. Alongside crankshaft grinding and machining, our team also carries out:

- Onsite crankpin machining: Repair and restoration of worn, scored, or damaged crankpin surfaces.

- Flange facing services: Restore damaged or worn flange faces to industry standards.

- Metal stitching services: A cold repair method for cracked or fractured cast iron components.

- Shaft journal repair: Restoring worn or damaged journals to the correct size and finish.