Portable Flange Facing Services

At Royce Onsite Machining, we provide professional onsite flange facing services throughout the UK and offshore. Our portable flange facing machining solutions restore damaged or worn flange faces to industry standards.

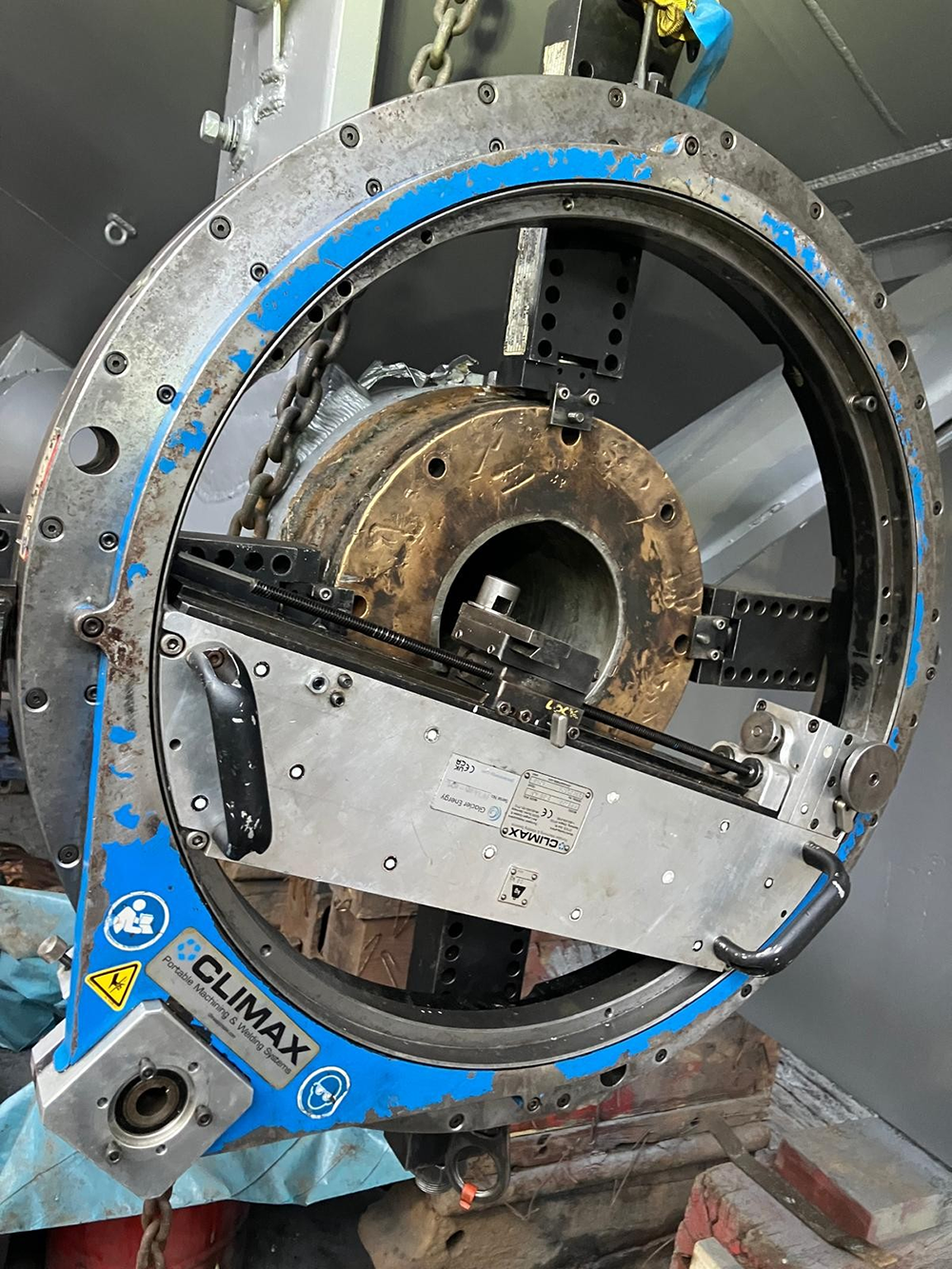

Using specialist in situ flange facing machines, we carry out accurate flange resurfacing directly at your site, on equipment where alignment work such as line boring may also be required.

Onsite Flange Refacing

We provide flange refacing services across a wide range of flange types and sizes. Our engineers routinely machine flanges from 1” to over 120” in diameter, including:

- Raised Face (RF) flanges

- Ring-Type Joint (RTJ flange facing)

- Flat Face (FF) flanges

- Compact and specialist flange designs

All flange facing services are carried out on site using portable equipment, avoiding the cost, risk, and delay of dismantling or workshop repair.

Surface Finish to Specification

Correct surface finish is critical to achieving a reliable gasket seal. Our flange facing machining delivers spiral serrated or phonographic finishes in line with ASME, API, and OEM specifications, ensuring compatibility with the selected gasket and operating conditions.

We control flatness, Ra values, and surface profile to meet specifications and support long-term joint performance. Where required, flange facing work may be carried out alongside portable milling to restore adjacent faces or mounting surfaces.

Flange Surface Restoration

Our flange face repair process removes corrosion, mechanical damage, and installation defects, restoring the flange face to within required flatness and surface finish tolerances.

Where required, flange resurfacing is carried out as part of wider maintenance or integrity work to return joints to service safely and efficiently. Where damage extends beyond the sealing face, particularly on cast iron components, flange face repair may be coordinated with metal stitching repairs to stabilise cracks before final machining.

Offshore & Marine Expertise

We have extensive experience delivering on site flange facing in demanding offshore and marine environments, including oil rigs, FPSOs, subsea flanges, and shipboard systems.

Our portable equipment and site-ready approach allow accurate machining to be carried out safely in live, space-restricted, and safety-critical locations.

Difficult Access? No Problem.

Our engineers are experienced in setting up in situ flange facing machines in confined or restricted spaces. Typical applications include heat exchanger flanges, pressure vessels, and awkward pipework where conventional machining is not possible. During on-site flange facing, we regularly deal with damaged fasteners and can carry out stripped thread repairs as part of the same visit.

Why Royce Onsite Machining?

With over 50 years of experience, Royce Onsite Machining delivers reliable flange facing services on live industrial sites where accuracy, planning, and safety are critical.

- Proven experience in on site and offshore flange facing

- Portable flange facing machines suited to a wide range of sizes and standards

- Engineers experienced in difficult access and safety-critical environments

- Work carried out to recognised industry and OEM specifications

- Practical, site-focused approach that minimises downtime and disruption

Frequently Asked Questions

What is flange facing machining?

Flange facing machining is the process of restoring or machining the sealing surface of a flange to achieve the correct flatness and surface finish. It is commonly used to repair damage, corrosion, or distortion that could otherwise cause leaks.

What are flange refacing services used for?

Flange refacing services are used to restore worn or damaged flange faces without replacing the flange. This includes correcting surface defects, restoring gasket contact surfaces, and ensuring compliance with flange standards.

What is RTJ flange facing?

RTJ flange facing involves machining the ring-type joint groove to the correct profile and dimensions to ensure a proper seal with the RTJ gasket. Accuracy is critical, as even small deviations can compromise sealing performance.

When is on site flange facing the best option?

On site flange facing is the best option when flanges are too large, difficult, or risky to remove, or when downtime must be kept to a minimum. It is commonly used during shutdowns, maintenance campaigns, and emergency repairs.

What industries commonly require on-site flange facing services?

On-site flange facing is widely used across industries where flanged joints are critical to safety and reliability. Typical applications include oil and gas operations (both onshore and offshore), Power Generation Services, Marine Repair & Maintenance and shipbuilding, Petrochemical Maintenance, as well as mining, heavy industry, and infrastructure and construction projects.