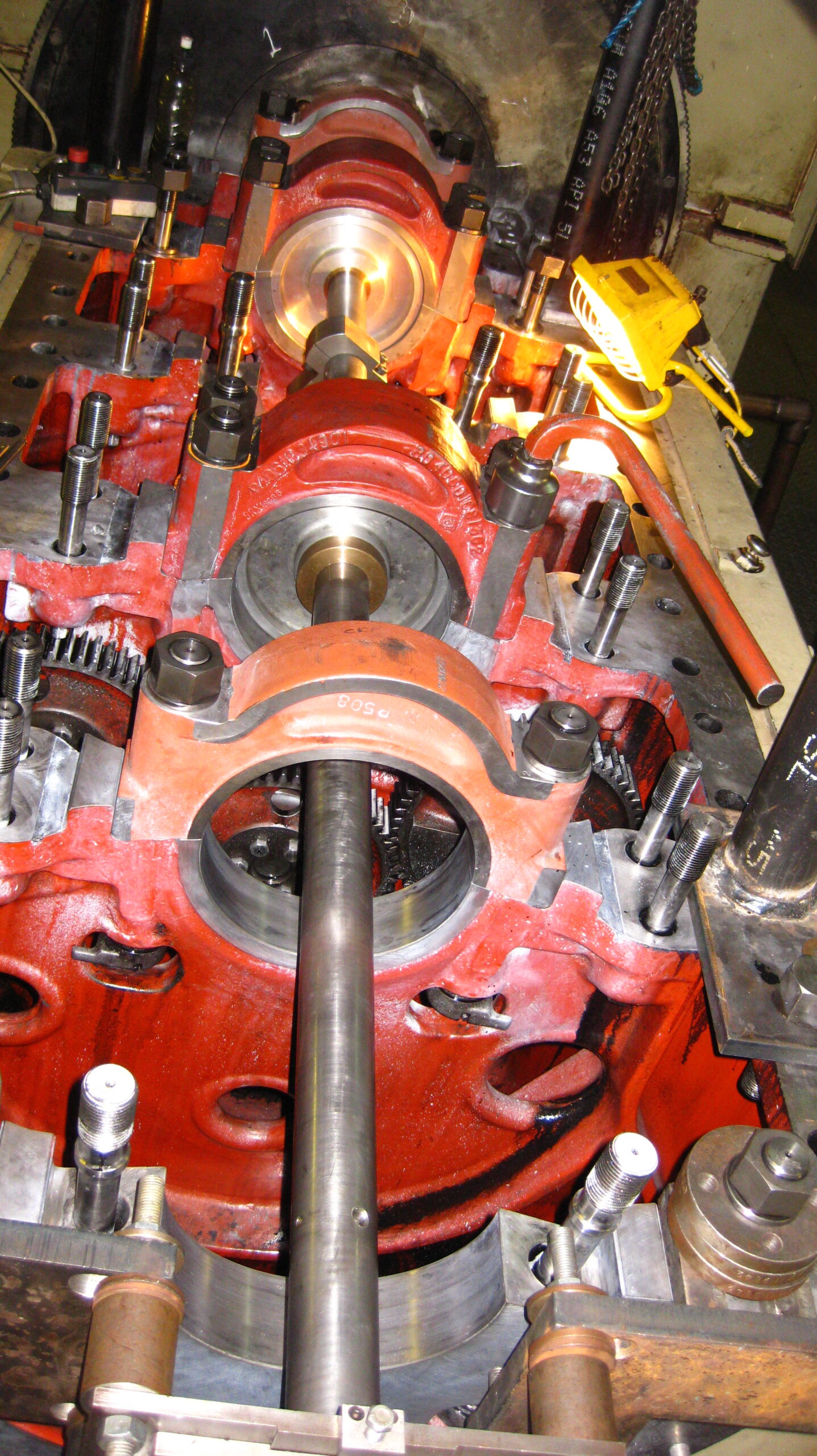

Diesel Main Bearing Pockets Line Boring

Royce Onsite Machining specialises in precision on-site line boring for large plant components that cannot be easily transported to a workshop. We expertly machine individual bores on items such as diesel engine bedplates, cylinder blocks, liner landings (including inserts), and other large equipment suffering from wear or erosion.

Our on-site line boring capabilities cover multiple in-line bores—such as main journal pockets—machined and aligned with high accuracy, even when spaced several metres apart.

Capabilities and Equipment

We work with bore diameters ranging from 25mm up to 1000mm as standard, with individual bore lengths up to 12 metres. Using state-of-the-art laser-guided boring equipment, we ensure precise alignment and machining to exact OEM tolerances.

Our latest laser alignment technology allows us to detect and correct even the smallest misalignments on diesel engines and marine or industrial plants of all sizes, helping extend operational life and improve reliability.

Custom Solutions and Design

For challenging or unusual applications, our in-house design team utilises advanced 3D CAD software (SolidWorks) to create bespoke tooling, enabling us to handle almost any line boring project with confidence.

Why Choose Royce Onsite Machining?

- On-site machining avoids costly and risky equipment removal

- High-precision laser-guided line boring for superior accuracy

- Expertise across diesel engines, marine, and industrial sectors

- Custom tooling and design capabilities for specialised jobs

- Dedicated to restoring your equipment to OEM specifications and extending service life