Crankpin damage is one of the most common causes of engine and machinery failure, often resulting from bearing collapse, lubrication issues, overheating or misalignment. At Royce Onsite Machining, we provide specialist in-situ crankpin machining and crankpin repair that restores damaged pins to precise OEM geometry without removing the crankshaft. This approach dramatically reduces downtime and eliminates costly dismantling and transport.

With decades of onsite machining experience, our team supports marine, power-generation and industrial customers worldwide, delivering accurate, reliable crankpin repairs directly at your site.

Comprehensive Crankpin Machining Capabilities

Our onsite machining equipment enables us to restore crankpins quickly and accurately while maintaining OEM specifications. Our capabilities include:

- Precision turning and grinding of crankpins from 75mm up to 2000mm diameter

- Repair and restoration of worn, scored, or damaged crankpin surfaces

- Onsite machining setup for minimal downtime

- Reprofiling and polishing radii to OEM specifications for optimal engine performance

- Complete alignment and tolerance verification during machining

Our portable orbital machining systems allow us to complete repairs on engines and crankshafts of any size, even in confined or remote locations. For crankshafts requiring additional restoration beyond the crankpin area, we also offer full journal and crankshaft machining through our Crankshaft Grinding & Machining service.

Our In-Situ Crankpin Repair Process

We follow a structured and controlled machining process to ensure accuracy and repeatability in every repair.

1. Inspection & Assessment

We measure wear, scoring, taper and ovality before machining begins, checking the crankpin’s condition and determining the required undersize. If the crankpin has been overheated or requires pre-machining stabilisation, we can carry out Heat Treatment & Crankpin Annealing.

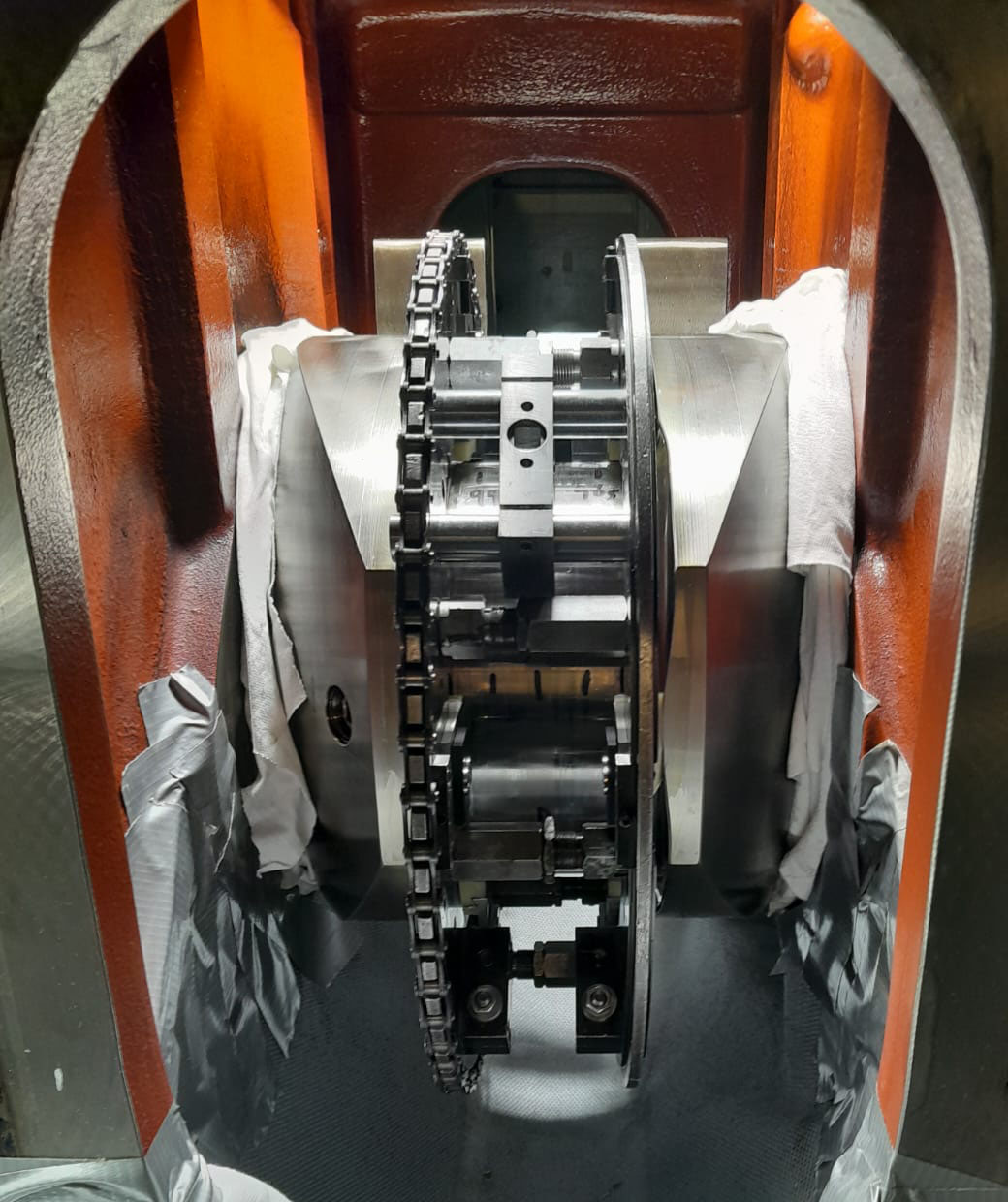

2. Precision Setup

The machining system is aligned using undamaged reference surfaces to maintain the original crankshaft centreline and ensure correct geometry.

3. Controlled Machining

The crankpin is machined to a precise undersize, removing damage and restoring roundness, straightness and correct bearing profile.

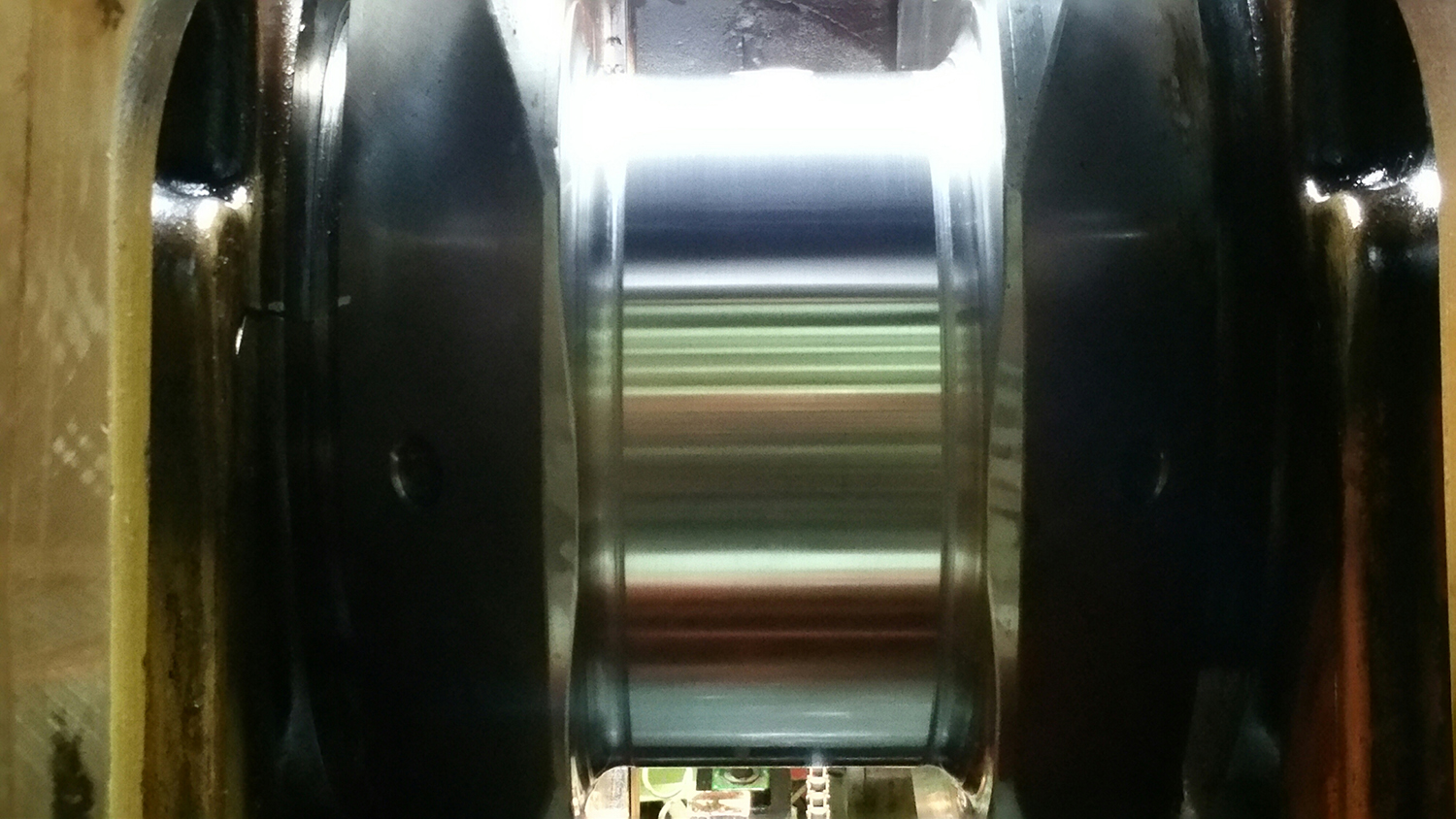

4. Grinding & Polishing

We complete the repair with a controlled finishing process to achieve the required surface finish for optimal bearing life and engine performance.

5. Verification

Final dimensional checks confirm the crankpin meets the necessary tolerances before the engine or machine is reassembled. If crankpin failure has affected associated journals or bearing housings, we also provide Shaft Journal Repair and Line Boring to restore correct engine alignment.

Where Our Crankpin Machining Is Used

Royce provides onsite crankpin machining for a wide range of industries and equipment, including:

- Marine main propulsion and auxiliary engines

- Power-generation diesel engines

- Heavy industrial engines

- Large compressors and reciprocating machinery

- Offshore and remote installations

- Emergency breakdown situations where rapid response is critical

Whether planned or reactive, our service ensures machinery can return to service quickly and reliably. Where bedplate or bearing pocket distortion has contributed to crankpin failure, our Diesel Engine Bedplate Line Boring service can restore accurate alignment before final assembly.

Why Choose Royce Onsite Machining for Crankpin Repair?

Customers rely on Royce Onsite Machining because of our precision engineering, rapid mobilisation and proven results across critical industries. Our key advantages include:

- Advanced orbital machining technology providing workshop-grade accuracy onsite

- Fast mobilisation across the UK and internationally

- Experienced onsite machining specialists trusted in high-stakes environments

- Available 24/7 for emergency repairs and scheduled maintenance

Our approach minimises disruption, protects equipment longevity and reduces overall repair costs.

Frequently Asked Questions – Crankpin Machining

Can crankpins be repaired onsite without removing the crankshaft?

Yes. Our portable machining systems allow crankpin repairs to be carried out in situ without dismantling the crankshaft.

What size crankpins can you machine?

We can machine crankpins from 75mm to 2000mm diameter, covering most marine, power-generation and industrial engines.

How accurate is onsite crankpin machining?

We achieve diameter, roundness and surface finishes that meet OEM specifications.

What causes crankpin damage?

Typical causes include bearing collapse, lubrication failure, overheating, misalignment, vibration and contamination.

How quickly can you mobilise?

Our team can respond rapidly for both scheduled and emergency repairs, ensuring downtime is kept to a minimum. We’re available 24/7 for emergency repairs and scheduled maintenance.