At Royce Onsite Machining, we specialise in shaft journal repair, journal machining, and the onsite restoration of worn or damaged bearing journals across pumps, motors, turbines, generators and marine equipment. Our orbital machining systems allow us to repair journals without removing or rotating the shaft, restoring precise geometry while dramatically reducing downtime and cost.

Precision Journal Machining Onsite

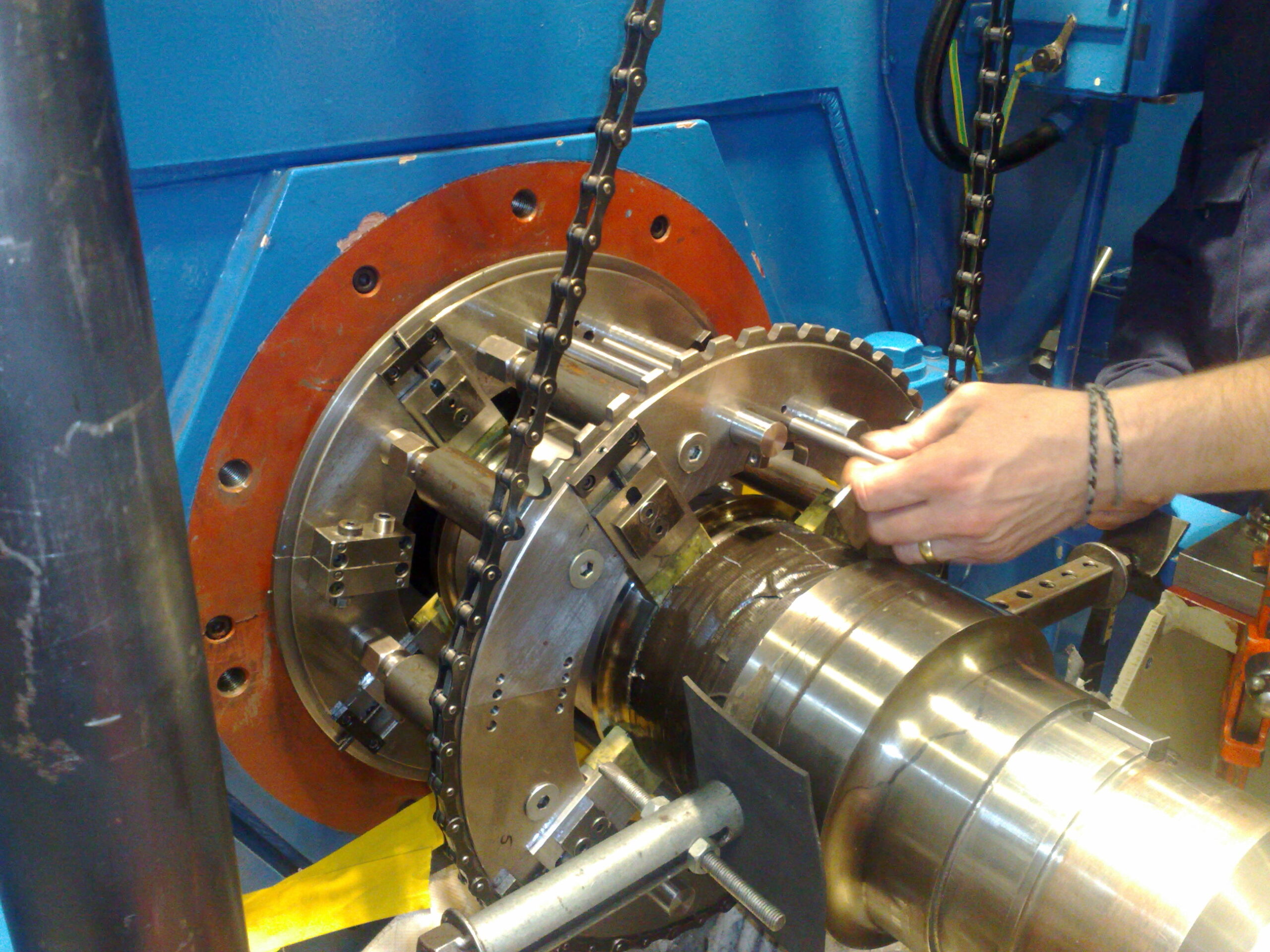

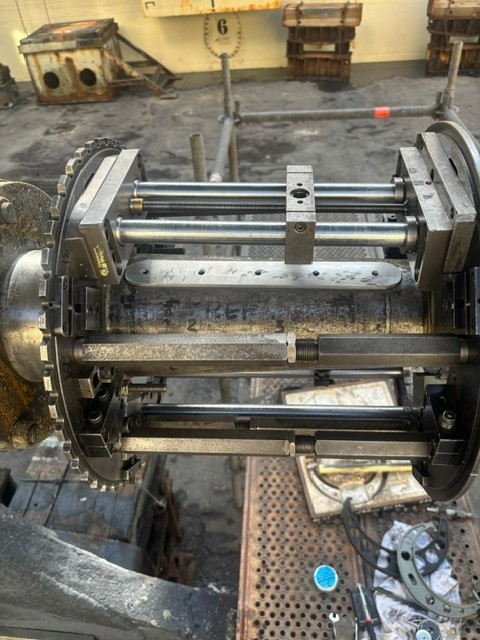

Most shaft failures occur at the bearing journal, where wear, scoring, corrosion or bearing collapse can distort the surface. Our in-situ journal machining process accurately restores the journal to OEM dimensions by referencing undamaged areas of the shaft. The machine rotates around the stationary shaft, maintaining the original centreline and ensuring workshop-quality accuracy onsite.

This capability covers:

- Pump shaft journal repair

- Motor shaft journal repair

- General shaft journal repair across all industries

- Bearing journal machining and final grinding

Whether the shaft is part of a turbine, motor, pump or marine drive, our process delivers a reliable, long-term repair.

Specialist Onsite Journal Machining and Shaft Repair Services

Turbine Shaft Journal Repair

For the most cost-effective turbine shaft journal repairs, our onsite machining technique offers an efficient solution. The equipment rotates around the stationary shaft, precisely referencing unworn areas at both ends of the journal or bearing radii. Our advanced technology ensures that the critical original centreline is maintained, achieving OEM tolerances with exceptional precision.

Generator Slip Ring Restoration

When generator slip rings become damaged or worn, even with shallow cooling grooves, we utilise our orbital machining equipment to restore them to optimal condition. With the addition of our specialised groove copying attachment, we can recover the required cooling depth, ensuring long-term performance and reliability.

Tailshaft Journal Machining

We provide professional onsite machining and polishing of tailshaft journals to remove signs of damage while maintaining precise concentricity and roundness within OEM tolerances. This repair is typically completed within just a few days, enabling rapid turnaround. Customers can expedite the process by pre-boring undersized bearings, ensuring minimal downtime.

Pump Shaft Journal Repair

For pump shaft journal repair and motorshaft journal repair, our innovative orbital machining system rotates around the stationary shaft, referencing undamaged areas on either side. This system allows us to machine and polish the shaft to a tight tolerance, creating a precisely undersized surface ready for a new bearing.

Fan Shaft Repair Services

Fan shaft repairs are a routine part of our orbital repair services. This includes repairing fan shafts and, when necessary, re-machining stub shafts to restore the keyway, particularly in cases where fretting damage has occurred.

Why Choose Royce for Shaft Journal Repair

Our approach is built around precision, efficiency and reliability.

- Precision Technology: Our onsite repair services are backed by cutting-edge technology, ensuring your equipment maintains original OEM specifications.

- Quick Turnaround: We prioritise efficiency, reducing downtime with fast, high-quality repairs.

- Cost-Effective Solutions: Save on equipment replacement costs with our proven repair methods.

- Industry Expertise: With years of experience, we specialise in the precision repair of turbine, pump, and fan shafts across various industries.

FAQs – Shaft Journal Repair & Journal Machining

Can shaft journals be repaired onsite without removing the shaft?

Yes. Our orbital machining equipment is designed to rotate around the stationary shaft, meaning most shaft journal repairs can be carried out onsite without dismantling the machine.

What types of shafts can you repair?

We repair a wide range of industrial, marine and power-generation shafts, including:

- Turbine shafts

- Pump shafts

- Motor shafts

- Generator slip rings / journal areas

- Tailshafts

- Fan shafts

- Crankshafts (via our crankshaft grinding machining and onsite crankpin machining services)

If a shaft has associated housing or structural wear, our line boring services can be used to restore bearing pockets or bedplates so that the shaft and housing align correctly.

How accurate is onsite journal machining compared to workshop machining?

Our orbital machining systems achieve workshop-grade accuracy onsite. Journal diameters, roundness and surface finish are restored to OEM specifications.

For applications requiring heat-affected zone correction after severe bearing failure, we offer heat treatment and crankpin annealing to stabilise the material before machining.

What causes shaft journal damage?

Common causes include:

- Bearing failure or overheating

- Misalignment

- Insufficient lubrication

- Corrosion

- Fretting or vibration

- Contamination in the lubricant

In some cases, adjacent components may also be damaged. For example, if fretting occurs in bearing housings, our line boring or metal stitching repairs may be required to restore the housing before journal machining.